My name is John Yater. I was born and raised in Hamilton Ohio, midway between Cincinnati and Dayton.

I am the Senior Design Engineer of special, made to order, material handling equipment. I utilize 30+ years of material handling experience, along with diverse skills, mechanical aptitude, and problem solving abilities to generate ingenious and innovative solutions to complex, demanding and unorthodox problems. Having the ability to “think outside the box”.

I leverage finite element analysis (FEA) and DFMA (Design for Manufacturability and Assembly) to make the most efficient use of my designs. A firm believer in Lean manufacturing philosophies and principles.

I am a “hands on” guy, not afraid to roll up my sleeves. I enjoy trying new things, and I’m naturally curious. I have an insatiable desire to learn and to solve problems, and find it highly satisfying. I have dabbled in a wide array of activities, from welding and woodworking, to programing CNC routers and working in Information Technologies (IT).

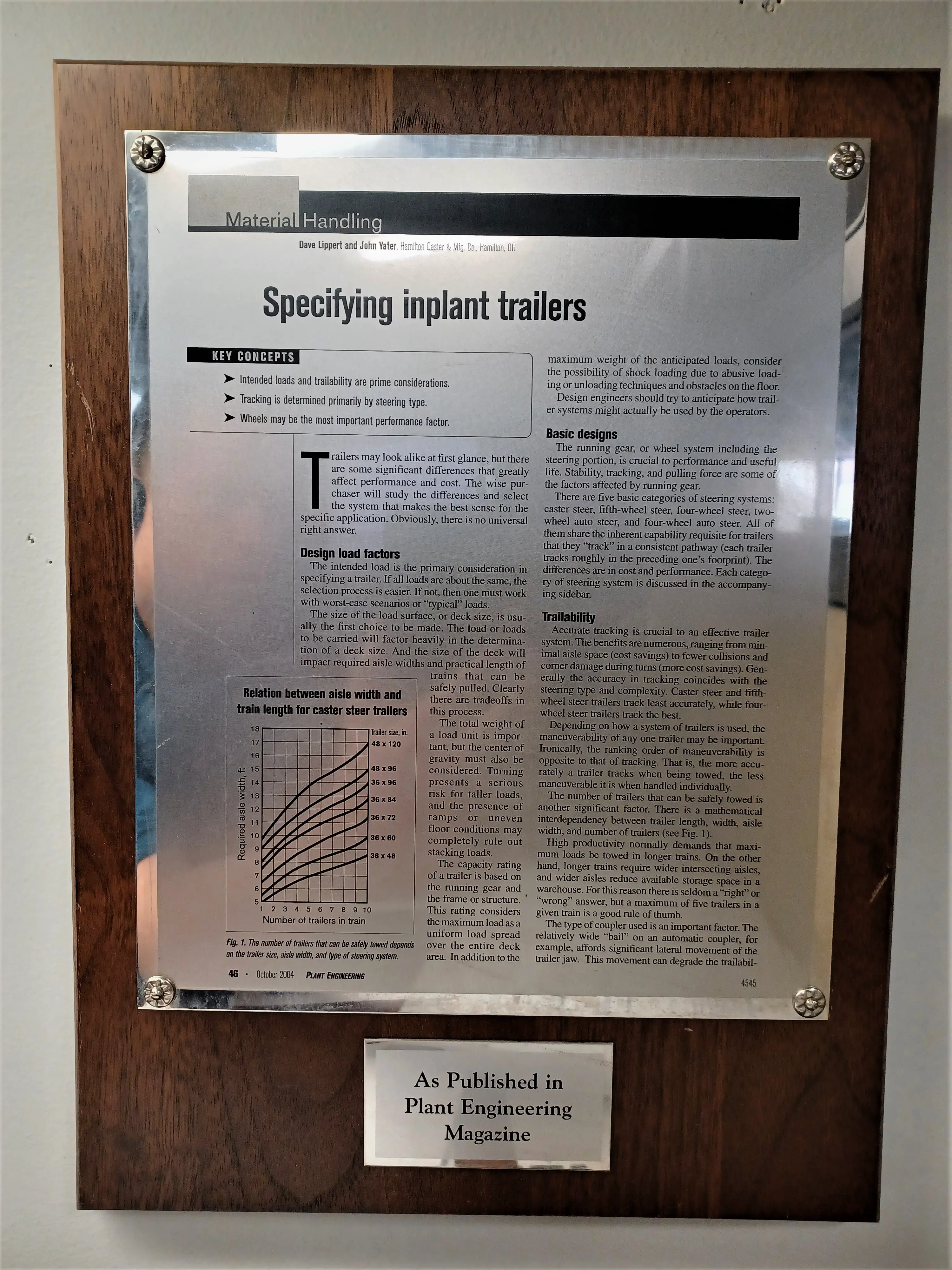

I have collaborated on an Invention and co-authored a white paper titled “Design Principles of In-Plant Trailers” that won the 2005 “Outstanding Material Handling Content Award” presented by the College Industry Council on Material Handling Education (CICMHE) of the Material Handling Industry (MHI).

My design experience is concentrated in the area of heavy duty / highly specialized structural steel and aluminum weldments fashioned into material handling trailers, carts, platform trucks and dollies that may include, or integrate with other material handling equipment like conveyors, scissor lifts, forklifts, order picker trucks, turntables, powered pushers, cranes, AGVs, ball transfers, and more…using components like hydraulics, slew drives, lashing rings, hoist rings, springs, shock absorbers, retractable ladders, nylon slings, wheel chocks, parking brakes, safety chains, trailer lights, winches, trailer jacks and much more…. serving a wide range of industries like Oil and Gas, Alternative Energy, Automotive, Aerospace, Defense, Mining, Construction, Warehouse and Distribution and so on..

You may find me mentioned in various places all over the internet. From magazines, to articles, blog posts, forums, white papers, and patents. Some examples include, but are not limited to –

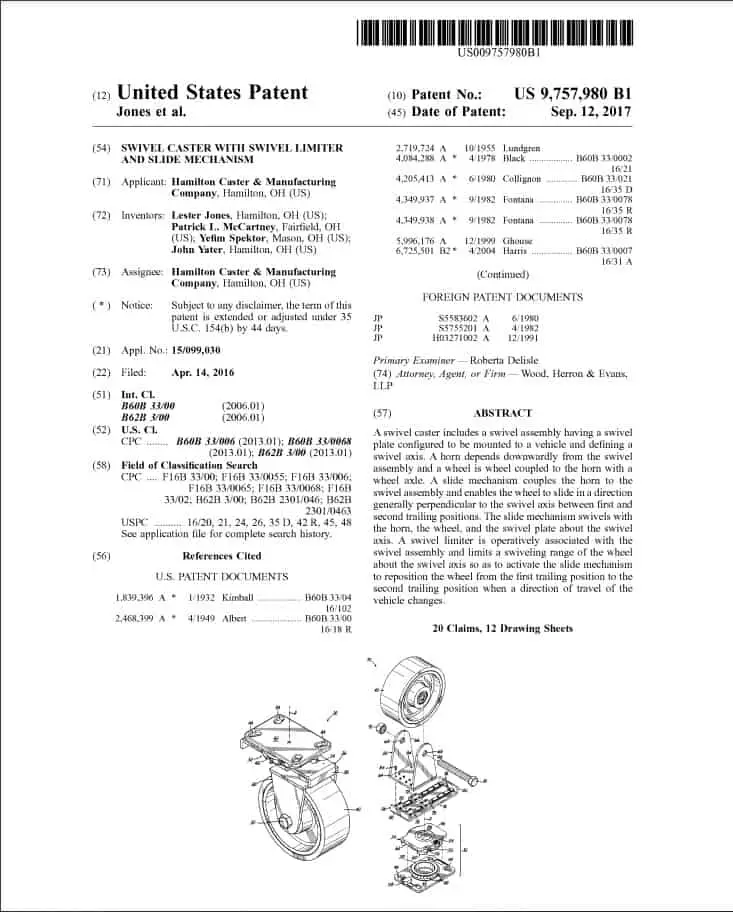

U.S. Patent number – 9757980 “Swivel caster with swivel limiter and slide mechanism”

A swivel caster includes a swivel assembly having a swivel plate configured to be mounted to a vehicle and defining a swivel axis . A horn depends downwardly from the swivel assembly and a wheel is wheel coupled to the horn with a wheel axle . A slide mechanism couples the horn to the swivel assembly and enables the wheel to slide in a direction generally perpendicular to the swivel axis between first and second trailing positions . The slide mechanism swivels with the horn , the wheel , and the swivel plate about the swivel axis . A swivel limiter is operatively associated with the swivel assembly and limits a swiveling range of the wheel about the swivel axis so as to activate the slide mechanism to reposition the wheel from the first trailing position to the second trailing position when a direction of travel of the vehicle changes .

https://patents.google.com/patent/US9757980

April 2014 edition of Machinery and Equipment MRO

April 2014 edition of Machinery and Equipment MRO Vol 30, No 2 Page 25 “Oil industry giant gets lean” “Hamilton Caster itself is a lean manufacturing practitioner and John Yater, a Hamilton design engineer, is one of the company’s biggest proponents of the concept.” “The trickiest part is getting a clear understanding of the customer’s application, intentions and desires,” Yater said. “We strive to solve customers’ problems and forge a relationship of trust.” https://issuu.com/glaciermedia/docs/mro2014april01

Hamilton Caster Blog – “Electric Trailer Spins Through Narrow Factory Maze”

Hamilton Caster Blog – “Electric Trailer Spins Through Narrow Factory Maze” “Before our trailer, they used a fork truck to move 30,000-pound dies,” said John Yater, a Hamilton design engineer. “Trouble is, …..” “Two inches doesn’t leave a lot of room for error,” said Yater. “One scrape could damage the load, or cause it……” https://www.hamiltoncaster.com/Blog/EntryId/904/Electric-Trailer-Spins-Through-Narrow-Factory-Maze

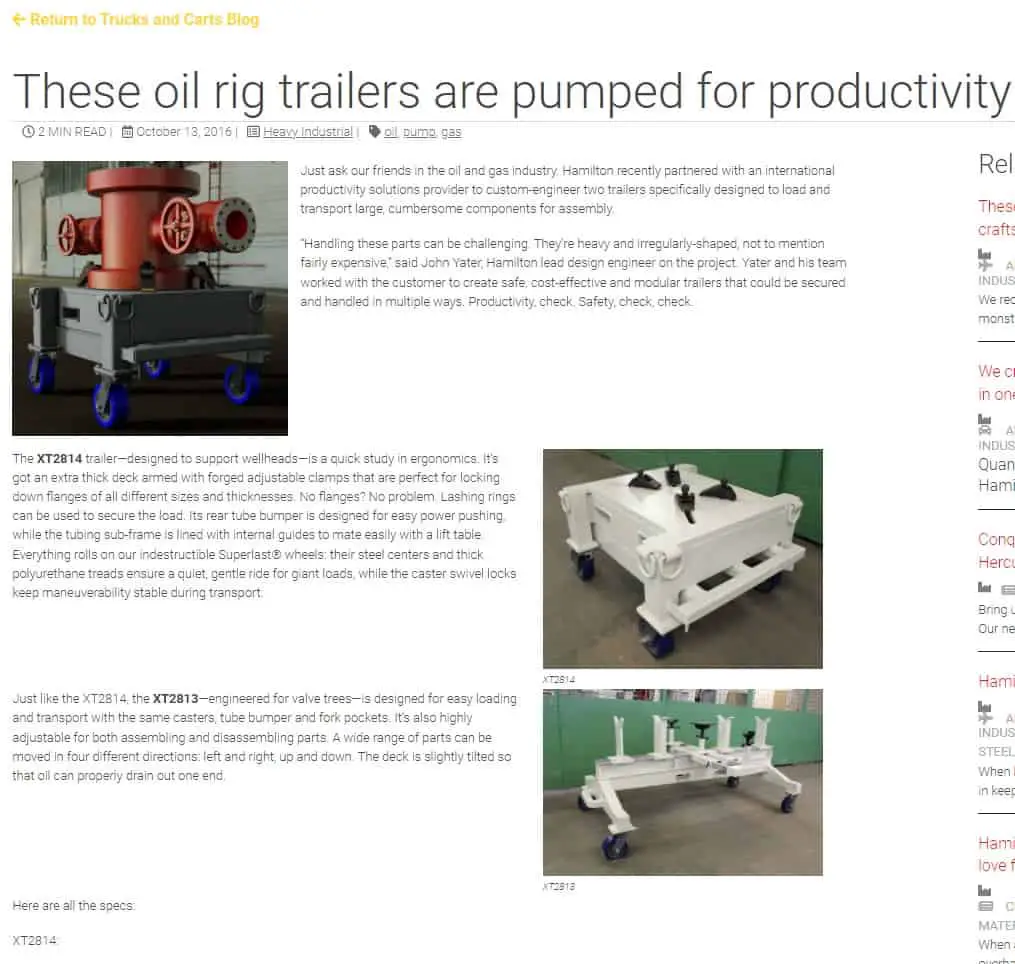

Carts and Trailers blog – “These oil rig trailers are pumped for productivity”

Carts and Trailers blog – “These oil rig trailers are pumped for productivity“

“Handling these parts can be challenging. They’re heavy and irregularly-shaped, not to mention fairly expensive,” said John Yater, Hamilton lead design engineer on the project. Yater and his team worked with the customer to create safe, cost-effective and modular trailers that could be secured and handled in multiple ways.

https://www.cartsandtrailers.com/Blog/these-oil-rig-trailers-are-pumped-for-productivity

MHI.org Press Release – “How to feel safe in an unsafe world? Torque Striping“

MHI.org Press Release – “How to feel safe in an unsafe world? Torque Striping” “That means no more wasted time checking bolt torques during inspection. Torque striping is…..”

Got questions about torque striping? Feel free to email John Yater.

http://www.mhi.org/media/news/16037

Plant Engineering Magazine – October 2004 “Specifying In Plant Trailers”

Plant Engineering Magazine – October 2004 “Specifying In Plant Trailers”

Trailers may look alike at first glance, but there are some significant differences that greatly affect performance and cost. The wise purchaser will study the differences and select the system that makes the best sense for the specific application. Obviously, there is no universal right answer. Design load factors The intended load is the primary consideration in specifying a trailer.

BY DAVE LIPPERT AND JOHN YATER, HAMILTON CASTER & MFG. CO., HAMILTON, OH OCTOBER 10, 2004

https://www.plantengineering.com/articles/specifying-inplant-trailers/

“Design Principles of In-Plant Trailers“

White Paper – “Design Principles of In-Plant Trailers”

Selecting any kind of material handling system can be challenging, especially when everyone is attempting to meet increasing production demands with limited space and budget. This is why every successful operation is taking a close look at factors beyond initial cost to total costs of ownership: maintenance, downtime, effciency, flexibility

and life. A trailer system inherently offers economy and flexibility. When that system is professionally designed and built from quality components selected to fit a specific application, it can offer much more.

http://www.mhi.org/media/members/14220/130101686044262931.pdf

Profiles –

Quora – https://www.quora.com/profile/John-Yater

HubPages – https://hubpages.com/@johnyater

Medium – https://medium.com/@johnyater