I have spent a good portion of my professional career designing Manual Material Handling Equipment. And over those years I have discovered that there are both advantages and disadvantages to Manual Material Handling. Later in this article we will discuss them, and then give examples.

First thing is first though. Lets answer the key question. What is Manual Material Handling Equipment?

Manual Material Handling Equipment can be defined as the human powered and manipulated equipment that enables the control, protection, storage and movement of materials not only throughout a company’s value added processes, but it’s entire supply chain.

When you talk about material handling equipment, none is as versatile with a low barrier to entry as Manual Material Handling Equipment. It doesn’t require batteries, gas or compressed air. It relies on human power and human control to use it. Manual material handling is more economical than other types of material handling equipment. The major downside is the ergonomics side. Manual Material Handling leaves the operator susceptible to injuries, both overuse and accidental.

Manual Material Handling Equipment – Advantages

Manual Material Handling Equipment is mobile – Compared to some forms of material handling equipment, Manual Material Handling Equipment is for the most part mobile.

Compared to other powered equipment that does the same job, manual equipment tends to be smaller and lighter.

Manual material handling equipment does not require a power outlet to charge or power the equipment. It doesn’t need compressed air to power the equipment. It doesn’t need gas to power the equipment.

Some forms of material handling equipment are large and semi-permanent. Manual material handling equipment can typically be moved around easier, making it more versatile.

Manual Material Handling Equipment is more economical –

Typically you can buy manual material handling equipment for a fraction of the cost of powered versions of the same equipment. This gives you a lower barrier to entry for those in the early stages of starting a business.

Powered material uses some sort of energy, that comes at a cost. Manual material handling equipment does not.

Manual Material Handling Equipment in power outages –

Not that it happens often, but during times of a power outage, manual material handling still works.

Manual Material Handling Equipment require less maintenance –

Manual Material Handling Equipment tends to be simpler in nature, with less moving parts, which equates into less maintenance that the equipment requires.

Manual Material Handling Equipment – Disadvantages

Manual Material Handling Equipment and Ergonomics – With manual material handling equipment you must take into account the ergonomics of the application. Work place injuries has a major impact on the bottom line of business. Steps must be taken to minimize the potential for injury.

There are many resources out there that can help you balance the risks of injury, versus the productivity of the application.

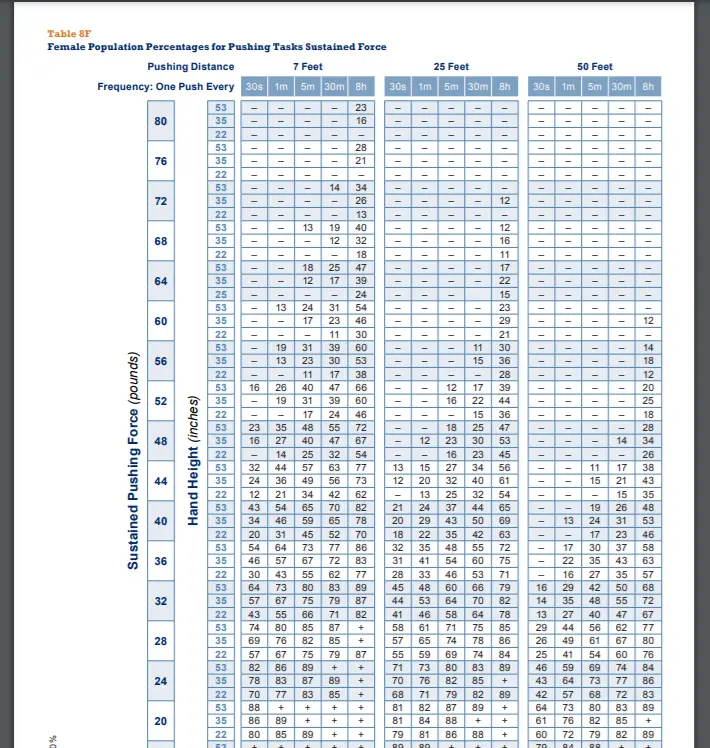

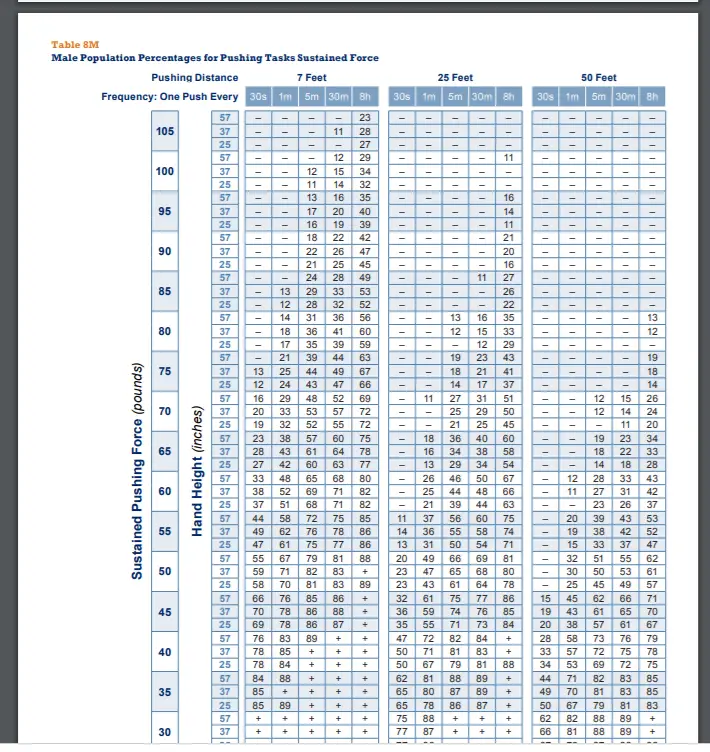

One of my “go to” resources is the Liberty Mutual tables for Manual Material Handling. It helps you evaluate the following tasks. Lifting, Lowering, Pushing, Pulling and Carrying. It can be found at – https://libertymmhtables.libertymutual.com/CM_LMTablesWeb/pdf/LibertyMutualTables.pdf

Another good resource is the Ergonomic Guidelines for Manual Material Handling brought to you by a collaboration from MHI, NIOSH, CDC, Cal/OSHA –

https://www.cdc.gov/niosh/docs/2007-131/pdfs/2007-131.pdf?id=10.26616/NIOSHPUB2007131

While the above helps some, it is hard to make a correlation between an acceptable force that someone can exert, and the load that is to be moved. One way is to buy a push/pull gauge for a couple hundred dollars and measure it yourself. The gauge to the right can be bought at Amazon.

Accuracy 0.2% or better of FS (Full Capacity). Hold Peak Tension or Compression load reading until reset. Peak or Track Mode. 500 reading can be recorded on internal memory for later viewing or download.

Menu driven, digital graphic LCD display

An easier way to check the ergonomics of a Manual Material Handling application

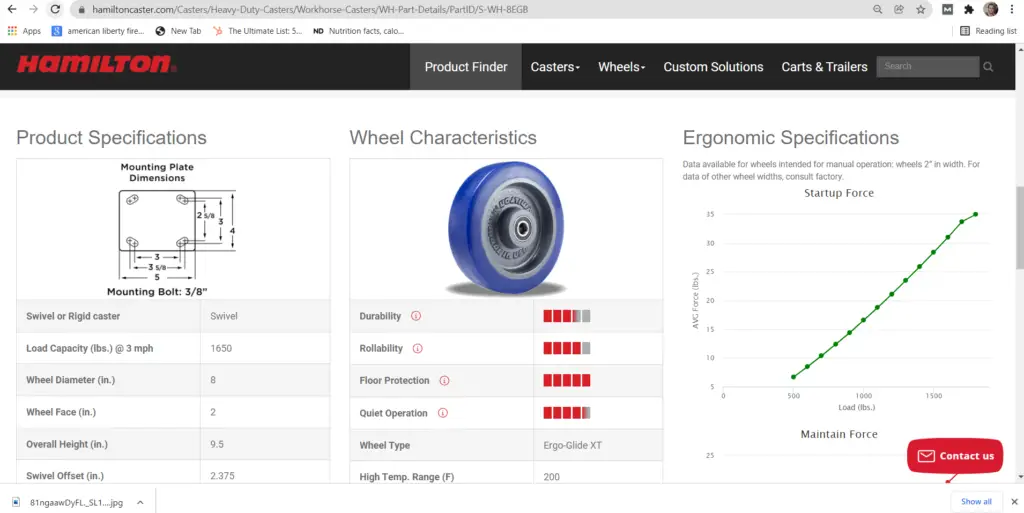

You could choose to follow my method of choice by using Hamilton Caster’s ergonomic data found at the part detail level for each caster. For an example, Hamilton’s S-WH-8EGB caster requires a startup force of 28.4 lbs when moving a 1,500 lb load. Using the Liberty Mutual Tables, it is easy to determine that 85% of the female population can push that load 7ft once every 5 minutes. You can also note that 88% of the male population can push that load 50ft every 5 minutes.

Examples of Manual Material Handling Equipment

Carts / Platform Trucks – Platform Trucks and carts are some of the most widely used non powered material handling equipment in the industry. They come in many different shapes and sizes. From tiny carts that are 18″ x 24″ and carry a couple hundred pounds, to 60″ x 120″ platform trucks that can carry 4,000 lbs. To put things in perspective, that’s the weight of a car.

Casters – Casters are very versatile. They can turn almost anything into a cart. You can put casters on cabinets, tables, work benches, ladders, racks, machines, chairs, computers, etc. The list is almost endless. You can even mount casters under large things like buildings.

Engine Hoist – Engine hoists serve a very narrow niche, those who need to remove an engine out of a car. Engine hoists typically have casters so that you can position them where needed. They can also be pushed over to an engine stand and transferred to it. Engine stands are used to hold and manipulate an engine while working on it.

Gravity Conveyor – Gravity conveyors are used heavily next to machines like saws, punches and shears. They are also used to empty out semi trucks. Gravity conveyors can be mounted horizontally or on a slope to use gravity to help propel the products that will travel over the conveyor

Jacks – Jacks are used to lift things that are heavy, cumbersome, or just downright dangerous to attempt to lift by hand. Jacks typically have a handle that the operator cranks, and that work is multiplied by a mechanical advantage of the machine.

Load Binders – Load Binders are used to crab two lengths of chain and provide tension in order to secure materials for transport.

Load Locks – Are adjustable bars that are used in semi trailers to block in a load and help keep it from shifting during transit.

Machinery Skate – A very small dolly that have wheels that are fixed and are used to move machines, or things of that nature in a straight line.

Pallet Jack – Is a mixture of a jack and a dolly that can be inserted under a skid or a pallet, jacked up, and then pulled around on the wheels of the pallet jack.

Pry Bar – Like a huge crowbar on wheels, pry bars, or johnson bars as they are sometimes called, are used to lift heavy material in order to insert another piece of material handling equipment under them like a dolly or a machinery skate.

Rolling Ladder – A ladder with casters mounted underneath to allow it to be rolled from one place to another. Then either the wheels are retracted, or some other type of brake is applied to keep the ladder from rolling while people are on it.

Shelf Truck – A cart that has a couple shelves in which product can be sat on. Shelf trucks make efficient use of floorspace by effectively increasing the net storage space that occupies that floor space.

Shopping Cart / Bascart – Shopping Carts are very common and used at almost every grocery store. Either made of wire, or extruded plastic, they are only designed to carry a few 100 lbs.

Strapping Cart – A strapping cart, or banding cart is used to carry steel banding and the tools needed to secure product for shipping. Commonly used to strap product to skids, strapping is a very versatile piece of material handling equipment.

Tote – A heavy duty box made of plastic, cardboard or other mater, that is economical to buy in large quantities. Totes are typically nestable, so that they do not take up a lot of space when not being used.

Two Wheel Hand Trucks – A small dolly with a load bearing nose which holds material and a handle that the operator controls the dolly with. When the dolly is leaned back, the load brakes over the wheel, allowing the operator to balance it on the two wheels.

Wheel Barrow – A wheel barrow has a tub like container that holds material, two handle that protrude out the back, that the operator holds onto, and a single or double wheel on the opposite side. The operator lifts up on the two handles, and is essentially carrying between 1/3 and 1/2 of the load.

Winch – The non powered versions are used to secure loads for shipping and can be seen on most flat bed trailers.

Summary of the import aspects of Manual Material Handling Equipment

In summary, Manual Material Handling Equipment is a simple, highly versatile, economic piece of equipment that is mobile and not reliant upon outside sources of energy. It is ideal for moving light to medium weight materials due to the ergonomic factors.