In my time working in the Material Handling Industry, I have had people inquire about platform trucks or carts without having a good grasp of what a platform truck is. Take advantage of my 30 years of experience and expertise as we talk about what a platform truck is, and what it does.

Platform trucks are low cost, efficient and versatile pieces of material handling equipment. They consist of a horizontal platform supported by wheels used to facilitate motion through force applied by an operator. The wheel’s mechanical advantage allows the operator to move more weight than he could otherwise carry.

While at first glance, platform trucks may seem very simple. But looking at them through the lens of a material handling expert you will notice slight differences that drastically effect their performance. Join me on a deeper dive as we go in depth on the subject of platform trucks.

What a platform truck is and what they are used for.

Platform trucks are a common form of manual material handling equipment. Sometimes they are referred to as a platform cart, platform trolley or platform dolly. They come in many shapes, sizes and load carrying capacities. They can have various running gear options that change the performance characteristics of the cart.

Platform trucks are used anywhere that large, heavy or a lot of parts need to be moved. You may find them at your neighborhood home improvement store, nursery or grocery store. They are used extensively in warehouses and distribution centers. They are commonly used in manufacturing environments to move materials to machines and assembly stations. They can be seen at construction sites, stadiums, amusement parks. They are not limited by geography, they can easily be found around the globe.

Platform trucks are versatile in that they can be used for many different tasks. They can be found moving boxes and large unwieldy parts. People use them to move heavy parts that cannot be lifted by hand. They are used to move things into tight areas, where forklifts cannot fit. They can store materials that are waiting to be machined. They can be used to collect parts coming off of assembly lines. The applications are only limited by ones imagination.

Platform trucks are economical. Both a platform truck and a forklift can be used to move the same load from one point to another. The main difference is that a platform truck can cost a few hundred dollars, while a forklift can cost thousands. Platform trucks have a low threshold to entry, so even the smallest of businesses can afford to use them.

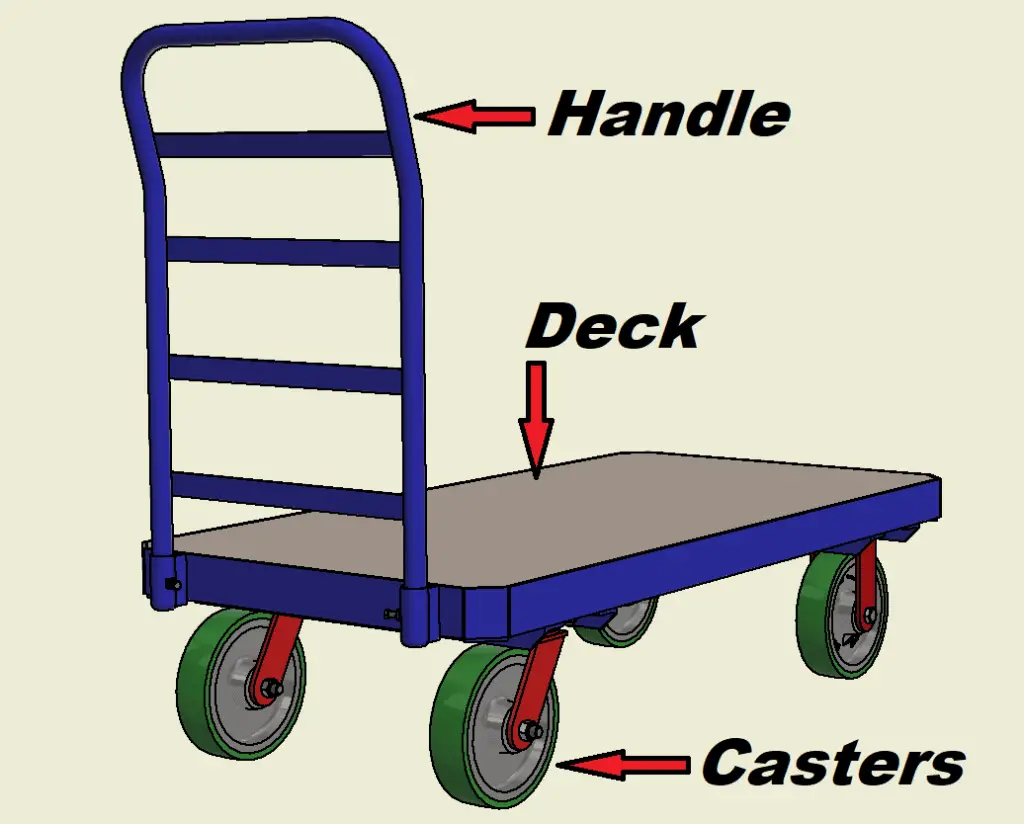

Platform trucks are simple. In there most basic form, there are three basic parts of a platform truck. The deck / frame is the main structure that will support the load. The running gear is the wheels / casters that are mounted under the frame. The handle is the structure that the operator uses to push the cart.

What platform trucks do.

Platform trucks are pieces of material handling equipment used to reduce the amount of force required to move materials by leveraging the mechanical advantage of the wheels. Platform trucks allow operators to move things without the aid of powered equipment like a forklifts. They are also used to hold materials that are either too big or too heavy to be done so by hand.

Platform trucks keeps the costs of moving materials low, since they are relatively inexpensive compared to other forms of moving materials. A platform truck with a capacity of 4,000 lbs may cost between $500 and $1,000. A forklift with the same capacity may run as much as $30,000.

How to use a platform truck.

Platform trucks are simple and easy to use. When loading the cart you may want to make sure the load is stabile and will not shift or fall when the cart is put into motion. When possible, push the cart instead of pulling it. When parking and unloading the cart, care must be taken so the cart doesn’t roll away.

Stabilizing the load on the deck can be done many different ways. One option is covering the deck with a non slip surface like rubber, or adding grit to the paint. Another way is to add a lip around the deck, or at each corner. Lashing rings, ratchet straps and winches can all be used to secure the load.

Pushing the cart from the swivel caster end is the preferred method. Pushing is superior to pulling in that more force can be generated and pushing is more ergonomic. Pushing carts keep the operator from twisting around to see where they are going. Pushing ensures that you are looking in the direction that you are traveling, and is therefore safer.

When parking a cart, do so in a way that the cart does not roll away. When there is a slight slope, park the cart transverse to the grade instead of in line with the grade. Apply caster brakes or floor locks if equipped. Swivel locks locking two swivel casters at 90 degrees to each other is an effective means to keep a cart from rolling away. Always avoid parking carts on steeper slopes as a runaway cart can cause damage to itself, the material its carrying and anything in its path.

Parts of a platform truck

The horizontal platform that carries the load is called the deck. The running gear is a conglomeration of wheels mounted in both swivel and rigid rigs to make casters, or wheels without rigs often called load wheels. Last, but not least, the handle is what the operator pushes or pulls to provide motion.

The deck can be made out of many materials, like steel, wood or aluminum. Each material has its own advantages, and disadvantages. Wood is quiet and protects the load. Steel is strong and economical. Aluminum resists corrosion.

The running gear has a huge impact on the performance of the platform truck. The diameter of the wheels are directly correlated to the force required to push the cart. The larger the wheel, the easier it is to push, and the less impact bumps and crevices have. The wheel tread material also has an impact on the performance of the cart. Treads vary from various rubbers to high performance polyurethanes. Each tread material has its advantages and disadvantages. Bearings reduce friction that can be found between wheels and axles.

The handle is the structure that the operator pushes to move the cart. The height of the handle is an important factor of the cart’s ergonomics. Handles are usually removable to allow oversized loads to overhang the deck. Sometimes handles or racks are used to retain loads like boxes or bags. Handles come in many shapes and sizes.

Platform truck running gear arrangements

Platform trucks come with many styles of running gear arrangements. The most common are the two swivel and two rigid caster version. Then you have two swivel and two load wheels. There is the four swivel corner pattern. The tilt type diamond pattern. And the tilt type corner pattern. Each have their own advantages, and reasons for being used.

Carts with two swivel and two rigid casters are probably the most economical to manufacture. All you need to do is attach the casters through mounting holes with hardware. The handle should be mounted at the swivel caster end. Care should be taken to ensure the rigid casters are in-line with each other. Having them point in different directions will vastly increase the thrust loading on the wheels, making the cart much harder to push.

Carts with two swivel casters and two load wheels are similar in nature to the first cart, with the exception that the larger load wheels will reduce the overall force needed to move the cart. The load wheels are positioned further from the end than the swivels to ensure that they carry more weight, but not so far that the cart becomes unstable. A company that is in the business of building trucks use years of experience to balance those two aspects.

A platform truck with four swivel casters has the ability to push the cart in any direction. This can be very beneficial when space is tight. You can add swivel locks on the casters which allows the cart to function as a typical platform truck when the swivel locks are engaged. All swivel locks can be engaged in the same direction and the cart will only travel in a straight line. Locking all casters in different directions acts as a break, keeping the cart from rolling in any direction.

Tilt type platform carts have load wheels in the center of the cart, and either one or two swivels on each end. The operator can then balance the load on the two center load wheels, taking advantage of the lower friction of the larger diameter wheels. The distinct advantage of a tilt type cart is that is can be turned around in its own diagonal length making it highly movable. The main advantage of a four swivel tilt type over a two swivel tilt type is increased stability.

Ergonomics of a platform truck.

When if comes to the ergonomics of using a platform truck, there are 4 main factors to consider. The handle height. The physical size and shape of the handle. The force needed to start and maintain motion. The height of the deck. Taking these four factors into account when picking out a cart, will go a long way in reducing the risk of musco-skeletol injuries.

Handle height should be positioned in such a way as to be within the operators power zone. The power zone can be described as mid thigh to mid chest level. When not knowing the exact dimensions of an operator, a good range to accommodate most people is 40″ to 45″. The physical size and shape of the handle should be designed so that the hands are in a neutral position. The handle diameter should be large enough not to concentrate stress and hurt the operators hands. It should be small enough to allow the hands to wrap around it.

The force needed to initiate motion should be minimized to reduce the risks of injury. The force that is deemed acceptable can vary based on distance, frequency and height. A good general rule of thumb is to aim for 40 lbs or less force, to initiate movement from a resting position. Generally speaking pushing is viewed as safer than pushing, but each application has its own circumstances that need to be evaluated.

The height of the deck also plays a roll in the ergonomics of the cart. In theory you want a deck height tall enough to aid in loading and unloading by placing the material in the power zone of the operator. You also want it low enough to make the cart stabile.

Variations of platform trucks

There are many variations of the standard platform truck that are used to customize the cart to a specific application. One variation is to elevate the deck in order to make the cart more ergonomically desirable. Some raised deck platform trucks are adjustable, while others are not. The raised deck, when it matches a work bench height allows materials to be slid from the cart, to the work station and back. Raised deck platform trucks can be used as a mobile workbench, making them a very versatile piece of equipment.

Another variation is the caster steer trailer. It is basically a platform truck with the addition of couplers in order to allow the carts to be pulled in a train. Train of carts can be pulled throughout a factory, delivering materials to the point of use. Trailer trains increase productivity by increasing the amount of materials one operator can deliver. As the operator travels his route, he can drop off carts full of materials to workers, and pickup empty carts for the return trip to the warehouse.

Other uses for platform trucks

Some people who like the industrial look when it comes to interior design use platform trucks as a coffee tables. The years of wear and tear add character to the cart, making each one unique. Each of these pieces of furniture has their own story, which makes them interesting. Best of all this sort of re-use keeps old dilapidated carts from ending up in a landfill, thereby making the world a better place.