In my many years designing industrial trailers, I have incorporated pintle hitches on my designs and also designed trailers to couple with pintle hitches on tow vehicles. I hope you stick around and use my experience to help you better understand exactly what pintle hitches are, and how they are used.

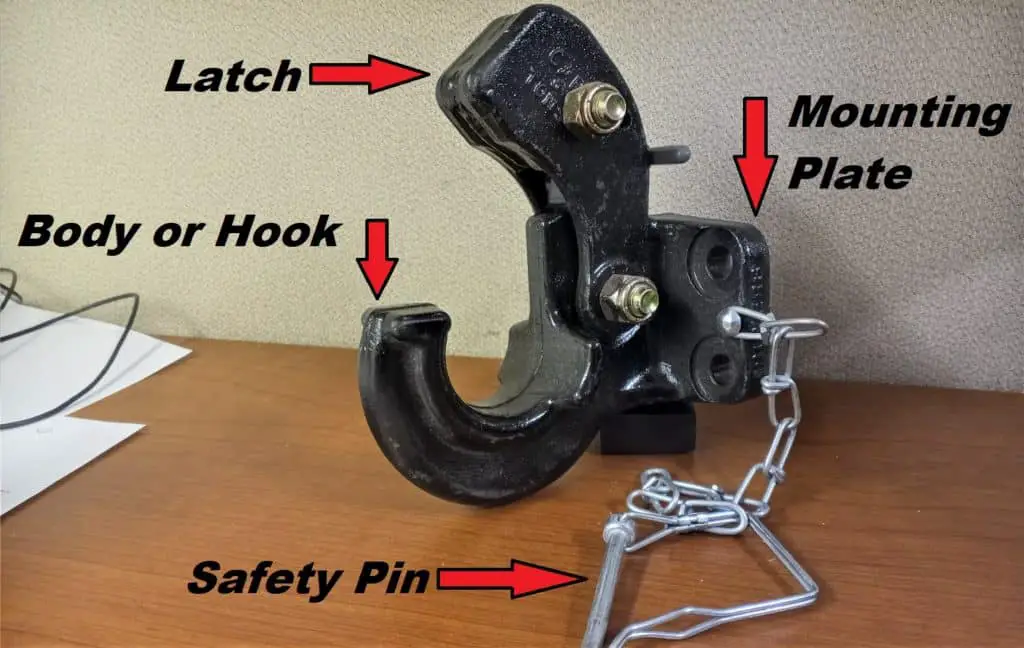

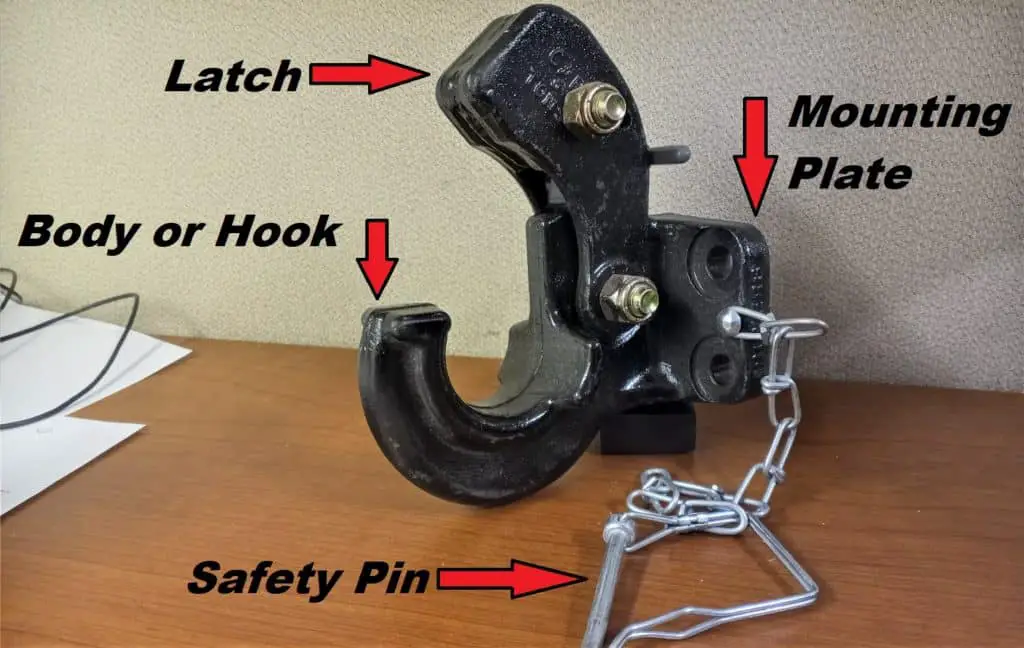

Pintle hitches are robust mechanical devices used to couple wheeled equipment together to facilitate towing. Pintle hitches have three distinct parts. A rigid frame called the body. A pivoting latch that gives access to the body and a positive locking pin that secures the latch in the closed position.

Sit back and relax as we go over just about anything you ever wanted to know about pintle hitches. We will discuss how they are used, how to install them, maintenance, types of pintles and applications for them. You will learn more about pintle hitches, than you ever though possible.

What Pintle Hitches are

Sometimes referred to as pintle hooks, pintle hitches are a tried and true rugged couple that have been used for over 100 years. Pintle hitches are typically manufactured from either forged steel, or cast alloy steel. Because of the shear volume of pintle hitches produced every year, their price point remains reasonable. They can be bought just about anywhere. From your neighborhood Tractor Supply Store, auto parts stores, industrial supply stores to online stores like Amazon, ebay, etc.

Pintle hitches are simple, efficient and easy to use. They are available in many shapes, sizes and capacities. Capacities range from 10,000 lbs to 150,000 lbs. There are swivel pintle hitches for off road applications like construction sites and military. There are spring loaded pintle hitches and air compensated pintle hooks for heavy duty over the road applications like double semi-trailers. There are pintle hitches designed to fit in receiver tubes so they can be quickly changed out. This quick change feature is nice if you tow more that one trailer with your pickup truck. There are adjustable pintle mounts allowing the tongue height to be modified in order to help keep the trailer tongue in a near horizontal state.

Pintle hitches are manufactured by companies such as SAF Holland, Curt, Premier, Wallace and Buyers. Most have overlapping offerings at the lower end that can be crossed over between each other. At the heavy duty end, and when is comes to more specialized pintle hooks and hitches, it is SAF Holland, Wallace and Premier that pulls away from the pack. Wallace Forge has the highest pintle hook rated at 150,000 lbs. If you are looking for the most value for your money, Buyers Products is who I would tend to favor. Bellow are links to each company’s pintle hook pages.

Buyers Products – https://www.buyersproducts.com/catalog/towing-12/pintle-hooks-and-pintle-ball-combinations-424

SAF Holland – Heavy duty – http://www.safholland.us/us/en/products/coupling-products/pintle-hooks—heavy-duty

SAF Holland – Medium duty – http://www.safholland.us/us/en/products/coupling-products/pintle-hooks—medium-duty

SAF Holland – Swivel mounts – http://www.safholland.us/us/en/products/coupling-products/pintle-hooks—swivel-mount

Curt Mfg. – https://www.curtmfg.com/towing-accessories/pintle

Premier – https://www.premier-mfg.com/product-category/couplings-pintle-hitches/

Wallace Forge – https://wallaceforge.com/pintle-hooks/rigid-mounted-pintle-hooks.aspx

What do pintle hitches do

Pintle hitches allow a trailer with a lunette (eye) to be coupled to a vehicle with a pintle. In some trailer trains, the pintle is mounted on the rear of each trailer, allowing one trailer to follow another. The connection of the two vehicles is the soul purpose that the pintle hitch fills.

How Pintle hitches are used

Pintle hitches can be used in a lot of applications. From over the road trailers, to ground support equipment to in-plant trailer trains. Below we will discuss briefly some of the different applications.

Pintle hitches are used to connect semi trailers that are being towed as doubles or triples. Pintle hitches used in over the road applications can see a lot stress. These pintles are generally very robust and are equipped with either spring or air cushions to alleviate shock loading. Pintle hitches used in this application should be inspected before every use.

Pintle hitches are used in the military for a few good reasons. They have a high strength to weight ratio. They positively lock both with a spring loaded latch, and a safety pin. The safety pin is a visual indicator that the hitch is locked. The latch / pin locking system creates two points of failure that would have to take place for the hitch to accidently open. The slop in between the pintle and the loop allows more degrees of articulation when traveling over rough terrain. The pintle / loop connection is easier, and faster to make than using a ball and socket system. A pintle hitch can be used as an attachment point for a winch when extracting a vehicle.

Pintle hitches are used for ground support equipment at airports. They are used on both the towing vehicles and the trailers being towed behind them when towing more than one piece of equipment. The slop between the pintle and the eye allows for a quick and easy connection…which is important with frequency that the connections are made.

Pintle hitches are used in construction. The slop in the connection allows for some trailer articulation without damaging the trailer or the coupler. There is some variations of capacity in that you don’t have to have the very same coupler to make a connection. This ability to have some mismatch makes the system more versatile.

Pintle hitches abundantly found in warehouse trailer trains. In the world of manufacturing, trailer trains are used to transfer materials from warehouses to manufacturing and back. Pintle hitches are economical, efficient and safe option when connecting trailers.

Pintle hitch types and applications

Rigid pintle hitches are by far the most common, and the most economical of all of the pintle hitches. These types of pintle hitches are typically bolted on using hardware meeting the manufactures specifications. It is the customers responsibility to ensure that what they are mounting the hitch to has sufficient strength to resist the towing forces the hitch will see in operation. Rigid pintle hitches are commonly seen on the back of tow tractors, dump trucks, fork trucks, burden carriers and other pieces of mobilizing equipment.

Swivel pintle hitches will be used in similar applications to the rigid pintle hitches above, with the exception the system need more swivel rotation about the axis of the tongue. These hitches are great for off road applications, as there is no binding at the coupler connection.

Cushioned Pintle hitches are very well suited for very heavy duty applications or over very rough terrain. Any application where there is shock loading in the forward/backwards direction.

Reciever mounted pintle hitch are well suited for vehicles that need to have couplers suited for multiple trailer types. There is a reciever tube permanently mounted to the vehicle that allows the operator to quickly switch out couplers, or just totally remove the coupler all together.

Adjustable height pintle hitches commonly used in conjunction with a reciever tube to give the further functionality of adjusting the coupler height. A good example would be when there is a need to tow a boat trailer, a utility trailer and a camper all with the same vehicle.

Combination pintle hitch / ball allows the user to tow trailers with both loop type couplers and socket couplers. without any changes to the pintle hitch.

How to install a pintle hitch

The first step is to determine how you want to mount the hitch. Do you want it bolted through a plate on the frame? Do you want a receiver mount so that you can switch couplers out quickly? Do you need a swivel mount?

The second step is to ensure that structure you will be mounting the coupler to has the ability withstand the forces generated when towing. You can do this with beam calculations or FEA if you have access to those capabilities. What you are mainly looking for is how the stress will flow through the coupler, into the mounting, and on to the frame. If all three parts are tied together and the stress will flow in an efficient manner, you are likely to be okay.

Next step is to follow the manufactures detailed instructions. Make sure that you use hardware of the right size and strength, and torque it to the proper specification bent bolting on the pintle hitch.

How to operate a pintle hitch

When it comes time to connect your pintle hitch to the trailers lunette (eye), go through your safety checks. Next, remove the safety locking pin. Release the latch and pivot it up and out of the way. Take the eye and lay it into the hook of the pintle hitch. Release and lower the latch. Last, but not least reinsert the safety locking pin.

Pintle hitch safety

In general, pintle hitches are a safe hitch to use. They have a latch, and a secondary pin to ensure the coupler stays closed. When the coupler is working properly, it is very unlikely that a uncoupling would occur.

When it comes to the installation, operation and maintenance of a pintle hitch, you must follow all of the manufacture’s instructions. You can find that information on data sheets, installation sheets and operation manuals for the specific product in question. That information is typically found on their respective website.

That being said, here is some general information when it comes to pintle hitch safety. It is intended to be used as general information, and never to replace the manufacturer’s specifications, instructions or manuals.

Never modify the pintle hitch in any way. Do not add to, or remove any parts. Do not weld to the pintle hitch. Refrain from grinding or machining any surface.

Do not strike it with a steel hammer. Doing so can adversely effect the strength and integrity of the part.

Never exceed the vehicles towing capacity, or rated bumper capacity.

Always check for missing, damaged or warn parts before each use. If wear exceed 1/8″ from the origin surface of the part.

Trailers with a rigid tongue, usually require a minimum of 10% tongue weight in order for the trailer to remain under control. Too little tongue weight and the trailer can get squirrely when going over bumps and things of that nature.

Pintle hitch maintenance

Maintenance relies heavily on visual inspections. The maintenance person should look for any sign of damage, rust or corrosion. The person ensure that all parts move freely without restriction. He should also the attaching bolts and connections for proper torque. Maintenance should be performed on a regular basis.

While you might think that greasing the pintle hitches moving parts would be a proper maintenance activity, it actually collects dirt, grime and sand, leading to more issue that it solves. Greasing a pintle should be avoided, unless you are directed to do so by the coupler manufacturer.

The hitch should also be inspected for excessive wear. When wear exceeds the manufacturer’s recommendation, the pintle hitch should be taken out of service.